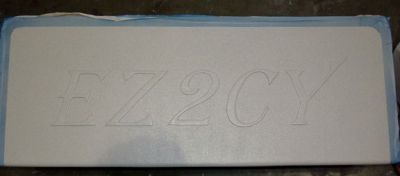

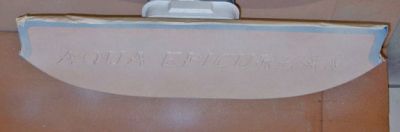

Hull & Deck >> Steps Project Description

Progress on this endeavor could only be accomplished with a collaborative effort involving many innovative products, companies and individuals. To find out more about these companies and products, select any one of the company links below.

Sponsors For This Project: Imtra Marine Products | MAS Epoxies

|

||||||||||||||||||||||||||||||||||||||||||||||||